News Center

Welcome to HAIDE Machinery! We are excited to invite you to join our big family

23

2025

-

05

Handling and Prevention of the Red Kiln Accident at 17.5m in the Φ 5.2m Rotary Kiln

In the cement clinker production line of precalciner kiln of MM company, the slope of the 5.2 m×78m rotary kiln is 4%, the three-speed supporting roller support, the Φ8.64 m× 42.8m high-efficiency online jet type decomposition furnace

In the cement clinker production line of precalciner kiln of MM company, the slope of the 5.2 m×78m rotary kiln is 4%, the three-speed supporting roller support, the Φ8.64 m× 42.8m high-efficiency online jet type decomposition furnace, the five-stage cyclone preheater, and the tower height is 105m. During the normal production period, the rotary kiln is fed 540t/h, the f-CaO is between 0.8%~1.3%, the decomposition rate of the raw meal entering the kiln is about 95%, the negative pressure at the outlet of the C₁ preheater is 4000 Pa, the temperature is 318°C, and the calcination of the rotary kiln system is normal.

The interior of the rotary kiln is built with refractory bricks of different specifications, models and varieties, which can effectively protect the outer cylinder of the rotary kiln from damage when the rotary kiln system is normally produced and calcined. However, in actual production, the use of refractory bricks is not satisfactory, and the service life can not meet expectations. In one year, MM company stopped the rotary kiln for 92.7h due to the accident of refractory bricks falling off in the rotary kiln, and directly lost about 28,000 tons of clinker output, 8 tons of ignition oil, and about 300,000 yuan of material maintenance and furnace construction labor costs. In this paper, combined with the red kiln accident at 17.5 m in the firing zone of the primary rotary kiln of MM company, the causes of the refractory bricks falling off of the firing zone are analyzed, and preventive measures are proposed.

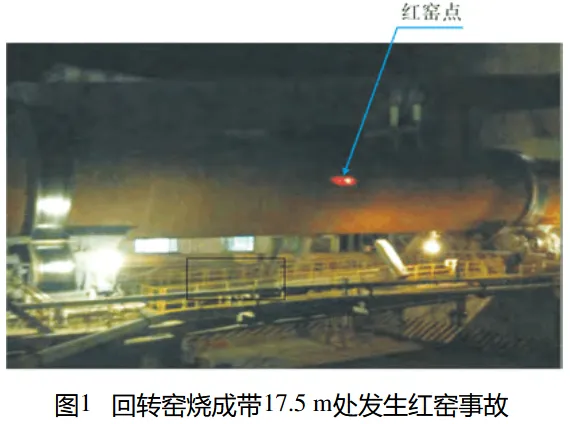

01 Accident occurred At 5:36 on February 18, 2016, when the fluorescence analysts in the laboratory passed under the rotary kiln and went to the kiln bucket to extract raw meal samples, they found that there was a red bright light of 300×400 square on the outer surface of the rotary kiln cylinder (see Figure 1); The kiln operator of the central control room was immediately informed of the on-site situation, and the kiln operator of the central control room immediately checked the screen of the cylinder scanner and found that the temperature of the rotary kiln firing zone was as high as 500 °C at 17.5m, and the temperature was 3×35 °C at 17.5 m, which was measured by a spot thermometer. The relevant personnel brought a fan and aimed it at the part to blow the air; The central control operator reduced the head coal from 16.5 t/h to 10 t/h, and the rotary kiln reduced the material to 400 t/h. After 45min of kiln skin repair, the surface temperature of the 17.5m kiln cylinder measured by the on-site post is still high (about 510 °C). The leaders of the post-operation department decided to stop the kiln at 6:30 on February 18, 2016.

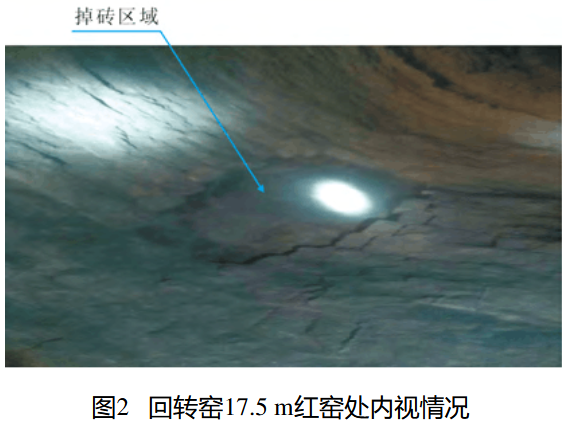

02 Reason analysis When the materials in the rotary kiln are emptied and the temperature in the kiln drops, the staff enters the rotary kiln to inspect the refractory bricks and kiln skins, and finds that the kiln skin is thin near the center point of the 17.5m red kiln of the rotary kiln, and the thickness is less than 150mm, and it is found that the brick area of the 17.5m red kiln is about 1 square meter (the brick variety is directly combined with magnesia-chrome bricks), and the thickness of the residual bricks is 43mm, see Figure 2.

(1) Check the records and screen data of the kiln operator in the central control room, etc., and find that at 0:05 on February 18, the current of the rotary kiln changed, and the kiln skin fell off many times, and the pressure under the grate of the grate cooler and the current of the clinker crusher fluctuated greatly, and the total kiln skin loss time was 2.45h. When the rotary kiln peels off a large number of kiln skins, in fact, the temperature of the outer surface of the firing belt cylinder has shown a rising trend, from the perspective of the cylinder scanner, the temperature of 17.5m in the rotary kiln firing zone at 0:46 slowly increased from 335 °C to 440 °C, and remained at a high temperature of 440 °C for nearly 5 hours for a long time, and no effective control measures were taken during this time period, which eventually led to the refractory bricks falling off and the temperature of the cylinder rising to 512 °C (red kiln). Because the kiln operator in the central control room did not pay attention to the change of the curve displayed by the cylinder scanner, the temperature of the cylinder continued to rise until the refractory bricks of the firing belt fell and were damaged.

(2) The refractory bricks at 17.5m have been used for 1 year and 3 months, and the thickness of the residual bricks is 135mm (the normal thickness of the standard bricks is 220 mm). Before the accident, there was a cylinder cooling fan at 17.5m in the rotary kiln firing belt for cylinder cooling, indicating that the temperature of the cylinder has already been high, but because of the protection of the kiln skin, the temperature is not more than 350 °C within the controllable range, and the kiln skin is normal. When a large number of kiln skins are dropped in the rotary kiln system and the temperature of the cylinder rises, multiple fans are not cooled in time to protect the growth of the kiln skins.

(3) The ingredients have changed a lot. Since the company's limestone procurement is mainly outsourced, it is difficult to ensure the homogeneity and stability of limestone quality, especially when the limestone is replaced by large piles, and the composition of raw meal fluctuates greatly. During normal production, the batching scheme of the raw material blending station is three components of limestone, silica and sulfuric acid slag. Before the brick accident in the rotary kiln, the batching scheme of the raw material mixing station was changed from the original three-component to two-component batching: limestone and sulfuric acid slag. At the same time, from the perspective of the raw meal component rate value of the vertical mill, the water hardness rate of the raw meal is low, and the aluminum oxygen rate is high. In this way, under the same calcination condition, the liquid phase of clinker in the rotary kiln increases, which makes the kiln skin of the firing belt unstable and improves the possibility of the kiln skin falling off of the kiln of the firing belt.

(4) Check the kiln head burner, find that there is no coking phenomenon and traces in the section of the kiln head burner, ask other staff, in the normal production stage of the rotary kiln, the kiln head burner has been calcined outside the kiln mouth (100mm away from the kiln mouth spacing), and there is no coking at the head of the burner and no coking in the section. In this way, it can be assured that the flame ejected from the burner is not deformed, and the flame is burning in normal integrity and will not damage the kiln skin.

(5) The ideological awareness of the management personnel in the section is weak. Because the company's firing section has no process technical management personnel. In the later stage of refractory brick use, when the composition of the ingredients changes, and the kiln skin falls off significantly, there is no effective analysis and correct guidance, which eventually leads to the damage of the refractory brick.

03 During the treatment process, the refractory bricks at 17.5 m of the rotary kiln firing zone are seriously damaged, the damage area is large (about 1 square meter), and the residual thickness of the refractory bricks around the damaged place is thin (45mm), so it is impossible to temporarily dig and repair them. If such a thin residual brick is excavated, the new masonry refractory brick cannot be firm and stable, and it is easy to fall off. In this regard, we will replace the refractory bricks in this section as a whole, and the residual thickness of the surrounding refractory bricks ≥ 110mm will be retained, so that the specific replacement part is 16.0 m ~ 21.2m. The masonry construction of refractory materials must be carried out in strict accordance with the relevant systems stipulated by the company for construction, masonry, supervision and technical guidance, and the following points must be achieved:

(1) Before construction, the simplified body of the kiln must be comprehensively inspected, and the uneven parts of the simplified body (welds and damaged parts of the brick machine) should be polished, and the debris in the kiln should be cleaned.

(2) Masonry pay-off: the longitudinal reference line of the kiln should be placed every 1.5 m along the circumference, and each line should be parallel to the axis of the kiln. The circumferential reference line is placed at 5m, and the construction control line is placed every 1m, and the circumferential lines should be parallel to each other and perpendicular to the axis of the kiln.

(3) The basic principle of masonry: the principle of three adhesion, that is, between the large surface of the brick and the simplified body, between the brick surface and the ring surface, to ensure that the surface is 100% tight, the surface is smooth, and the refractory brick and the kiln cylinder are reliably concentric during operation. It is necessary to avoid the following common problems in the masonry process of refractory bricks: climbing, washboard, inversion of the big and small heads, drawing, dislocation, inclination, serpentine bend, mouth opening, etc.

(4) When the refractory bricks are built to close, at the position of the last 7~8 refractory bricks, select the lock bricks and standard bricks of the appropriate size for reasonable matching and locking. Adjacent ring lock bricks should be staggered 1~2 bricks, the number of lock bricks in a ring shall not exceed 4, lock bricks can only use undisturbed bricks, can not use processing bricks, lock bricks can not be used continuously, and should be close to the kiln cylinder.

(5) After the refractory brick masonry is completed, the wedge iron is reinforced, the thickness of the wedge iron is 3 mm cold-rolled steel plate, which is required to be smooth, not curled, not twisted, and no burr, and only one wedge iron can be inserted between the joints of each refractory brick, and each ring of locking wedge iron shall not exceed 4 pieces, and it should be evenly distributed in the entire lock brick area.

04Precautionary measures

(1) Strengthen the sense of responsibility of the kiln operator in the central control room, and when there is an abnormal problem in the rotary kiln, the kiln operator in the central control room can find the problem in time and time, and can have the ability to prevent and deal with accidents.

(2) When the refractory bricks are used in the later stage, more attention should be paid to the changes of the kiln skin, and the normal operation of the rotary kiln calcination system should be ensured by adjusting the kiln head burner, simplified cooling fan and batching scheme. For the place where the residual thickness of the refractory brick is thin, the thickness of the kiln skin should be strictly controlled, and the kiln skin of the firing belt should not be too thin.

(3) Stabilize the raw meal batching plan, strictly control the quality of all incoming limestone, and the quality of incoming limestone cannot be unqualified; At the same time, when the limestone is distributed, the cloth machine is required to distribute the material evenly and orderly, and the fixed-point distribution is eliminated.

Related news